During the international event MAM 2024 Mediterranean Aerospace Matching, the project for the construction of the Taranto Grottaglie Spaceport was presented. This is a unique structure in the European Mediterranean area, from which it will be possible to carry out horizontal take-offs and landings of future space vehicles for the launch of payloads into orbit, suborbital flights, controlled re-entry from orbit, microgravity experiments and astronaut training.

The main structures, designed by a team comprising ADR Ingegneria, Proger, Rina Consulting and Architect Camerana, are a large hangar and a multifunctional building connected by a futuristic tunnel:

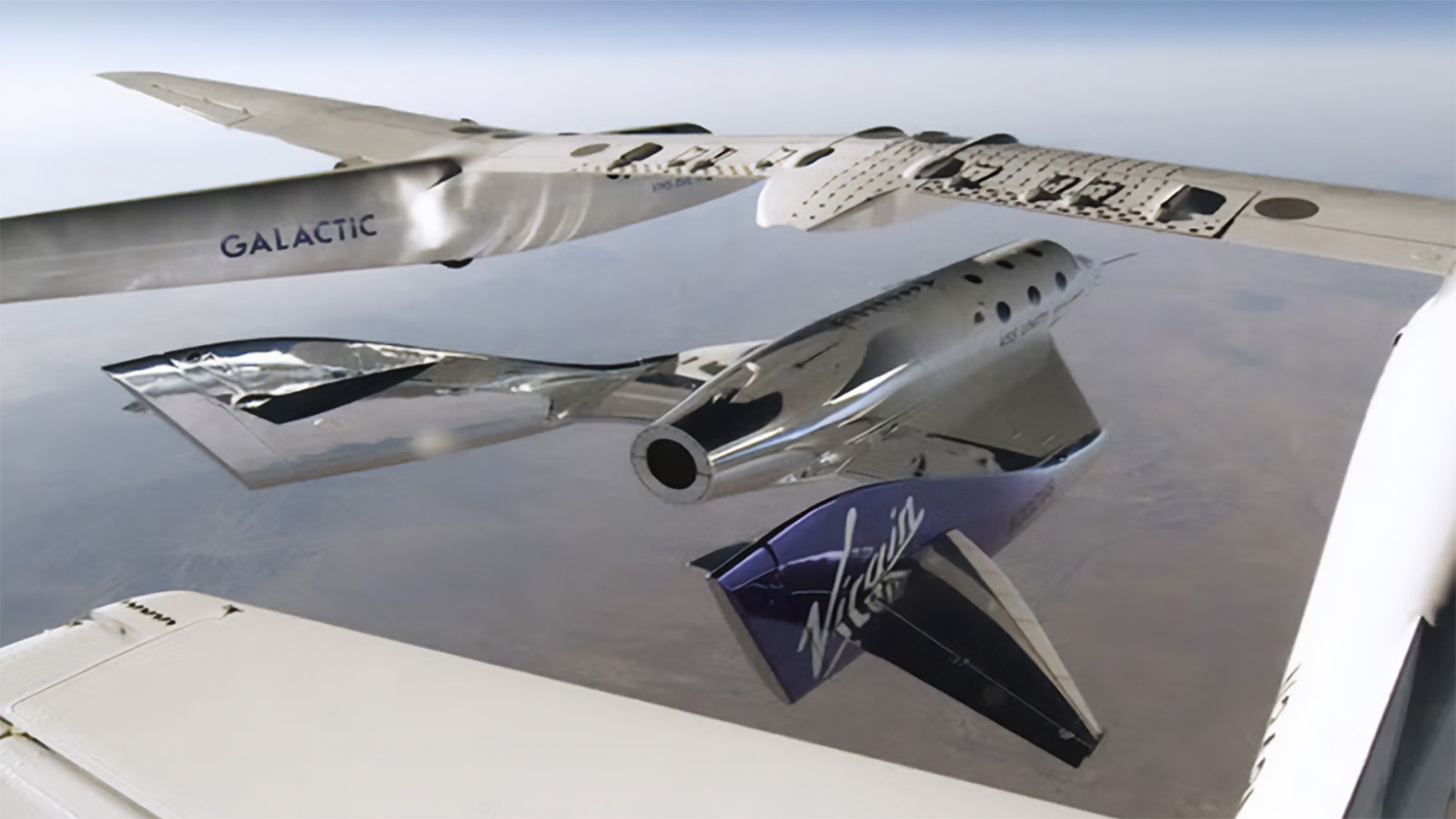

- The hangar (8,000 square metres) is designed to accommodate large aircrafts such as the Boeing 747-8, one of the largest aircraft in circulation, and carriers such as Virgin Galactic’s White Knight Two, used to launch suborbital spacecraft. The internal configuration has been designed to provide the flexibility required for different types of platforms, including atmospheric re-entry, as well as the medical, dressing and training centre rooms to support the crew, and the capacity to house the services required for pre- and post-flight payload processing. This included 8 laboratories, 3 with fume hoods for chemical/biological reagent operations, 5 ISO Class 8 clean rooms and 4 experimenters’ offices.

- The multifunctional building (5,000 square metres) will house a training centre, an aerospace start-up incubator, a visitor area, a museum and 7 laboratories to support the microgravity experiments made possible by the space access platforms.

The project carefully integrates logistical elements and state-of-the-art equipment into the local landscape, choosing colours and materials that harmonise with the existing environment in terms of landscape protection and environmental sustainability, and aims to achieve LEED Gold and Silver certification, thanks to Proger’s technical solutions that make complex and demanding structures such as the hangar and laboratories almost energy-neutral, while guaranteeing top-level performance for all systems.

Taranto Grottaglie Airport’s integrated logistics and technical platform is recognized as an aerospace hub of excellence for development activities, research and testing of innovative solutions, in addition to being home to a “Test Bed” area for drone testing. In 2014, it was designated by the Italian government and ENAC (Italian Civil Aviation Authority) as the site of Italy’s first and only spaceport, thanks to significant developments over the past two decades, starting with the 2006 land-side expansion and air-side modernization project carried out by Proger, which consisted of a runway extension and upgrade to allow the takeoff and landing of the Dreamlifter, the cargo plane carrying the fuselage parts of the Boeing 787 Dreamliner, assembled at the adjacent Alenia Aermacchi factory.