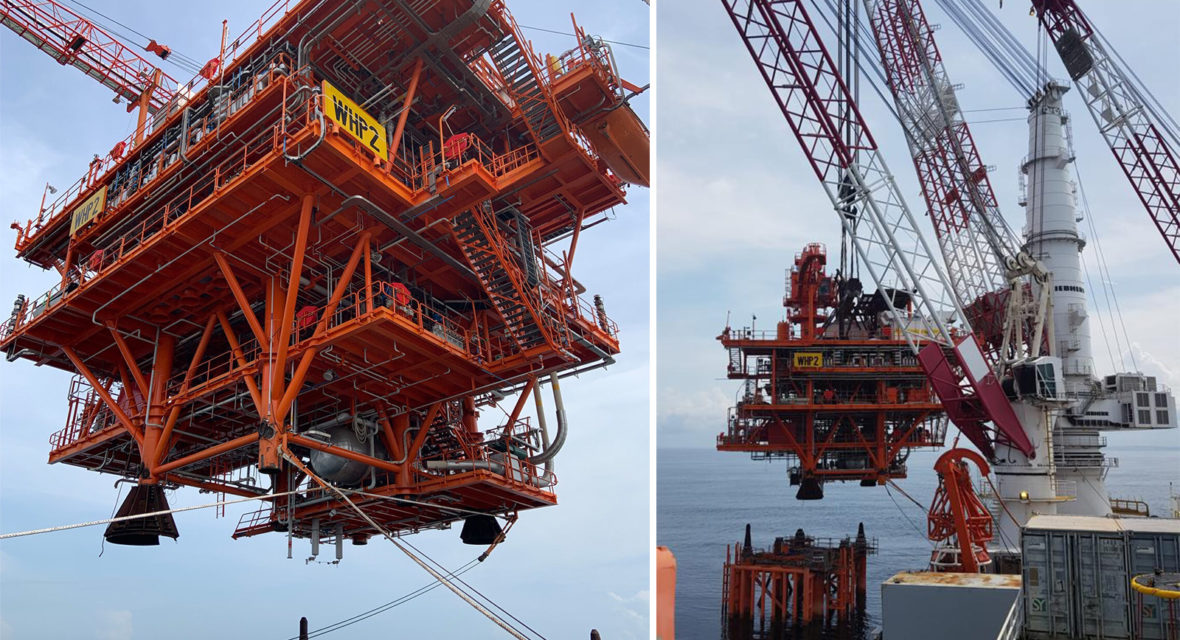

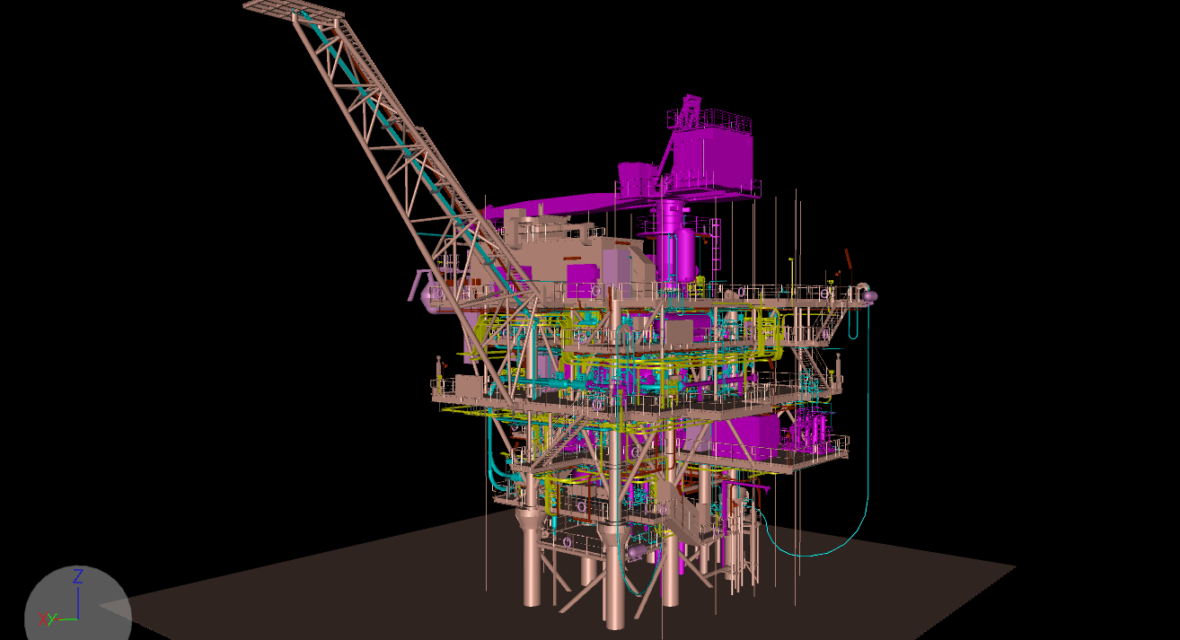

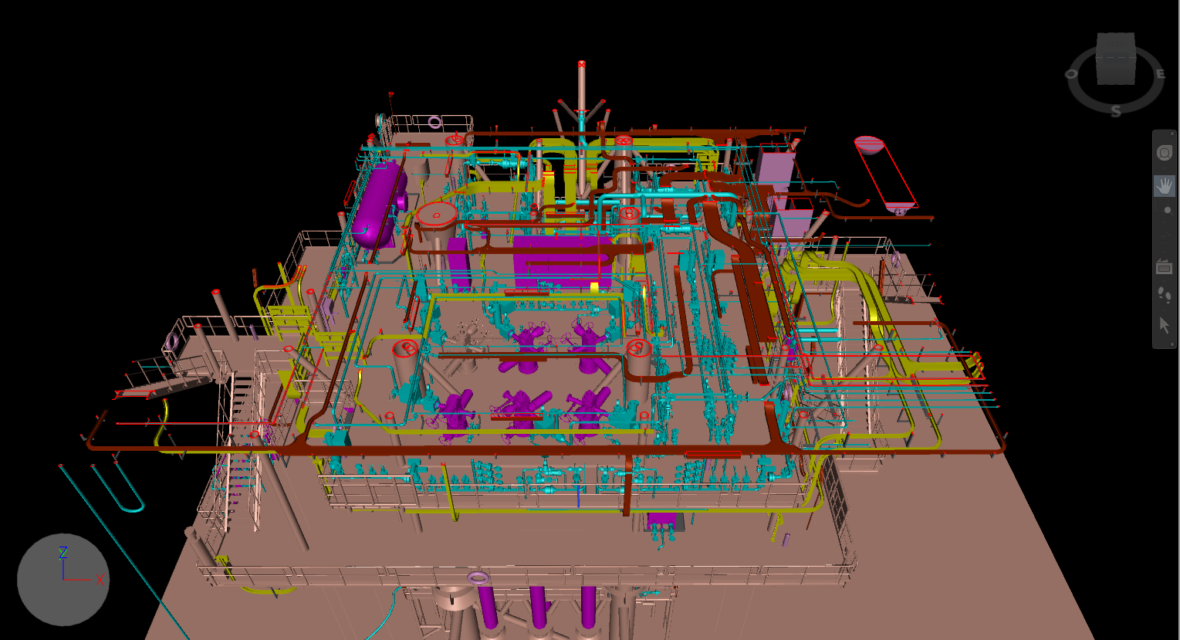

WHP2 Platform

Description

Proger, in JV with Antonini Group, is in charge of the EPC (engineering, procurement and construction) services for the construction and installation of the WHP2 platform and related equipment, transport to the offshore installation site, SIMOPS during jack-up drilling operations and start-up of the equipment.

The six-legged un-manned platform is designed to allocate n. 6 API 10000 X-mas tree and relevant flowlines equipped with HIPPS system, production manifold, n. 2 12” risers and n.1 10” J-tube. The main facilities are: n.2 12”x16” launching/receiving traps, Test Separator (7,5 m3 – #1500), Integrated Drains Vessel / Vent KO Drum (11 m3) connected to Cold Vent Boom, Vent K.O. drum Booster (4 kW) and Main pumps (30 kW), Chemicals and glycol Injection skid (n. 4 skids) and relevant storages, Diesel storage (10 m3) and Diesel Fuel filtration skid, Diesel Generators (185 kW), WHCP, Water and Foam Firefighting skid, Service Water tank, Sump caisson and relevant pump, Local Electrical Room (~60 ton, including ICSS, PMCC, Telecom cabinets, UPS, HVAC) Clean Agent system, lattice boom crane, life boat (POB 25) and rescue equipment, firefighting equipment, navigation aids.

Client

ENI Congo

Services

EPC

Location

Congo

Technical Data

Production: 12.000 BOPD, 600.000 SCMD

Depth: 30 m

Jacket weight: 550 ton

Top-Deck weight: 1.200 ton